Lasers can etch on pretty much any material. The most well known materials in the etching fields are covered metals, wood, acrylic, glass, cowhide, marble, plastic, and host of manufactured materials made explicitly for lasers. You can consider a laser a light source like a light – a light will discharge energy out surrounding it.

Laser checking is likewise alluded to as laser carving. Dissimilar to traditional carving, laser scratching needs no covers or synthetics. Certain individuals simply call it laser drawing and others call it laser etching yet fundamentally the strategy utilizes a PC controlled laser pillar to check a surface. It didn’t take long for the etching business to see the new lasers and soon lasers were being utilized for a wide assortment of modern applications including welding, heat-treating, carving and etching.

Furthermore, practically all materials can be laser engraved/laser checked. The light source name – LASER, is an abbreviation for Light Intensification by Invigorated Emanation of Radiation.

You can likewise cut metal with lasers. The laser metal slicing choice can be added to certain models of the laser cutting machines. The capacity to laser cut complex profiles can take out the requirement for extra activities, making laser cutting extremely practical. Lasers function admirably for cutting acrylic (Plexiglas), PETG, dainty polycarbonates (Mylar), styrene extended PVC (Sintra), wood, paper and texture.

Laser carving should be possible on numerous different materials including record, rock, tempered steel, cowhide, arborite, glass, mirrors, and premium hard woods. Furthermore, laser cutting offers a predominant cut-edge quality with equal sides and no burrs.

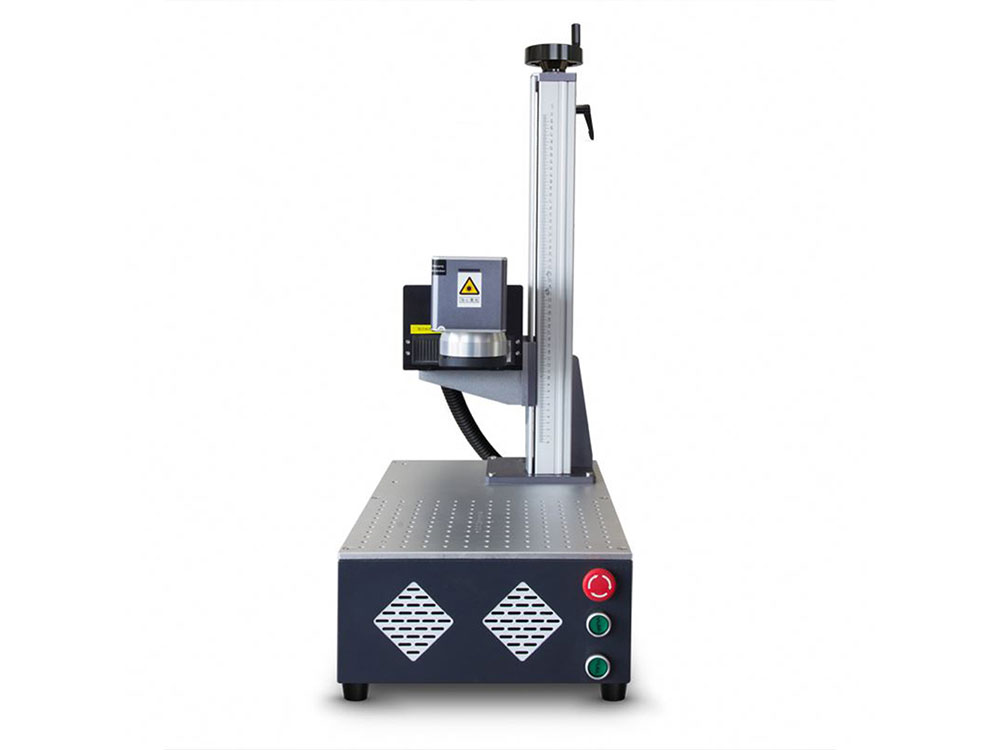

Enterprises that utilization laser checking incorporate the limited time, designing and clinical ventures. It’s a cycle where material is permanently set apart at some extremely quick paces (milliseconds per character). fiber laser engraving marking machine A portion of the things that C02 lasers and C02 laser frameworks can be utilized for as far as checking and scratching glass or quartz are float glass plants, assembling of glass entryways and windows, long-lasting sequential numbering, ANSI wellbeing data, client logos, enhancing or specialty glass fabricating, producing information connected with plant, the creation date and line, or potentially part numbers.

Laser checking of glass by C02 lasers on the fly or while moving can be a fantastic expansion for the overwhelming majority modern conditions and the applications for glass stamping. Since no inks are utilized in the denoting, the administrations are both long-lasting and the cycle is caring to the climate. You can stamp effectively in clusters from 1 to 10,000.

There are no consumables involved so the working expenses are negligible, and the laser framework, if appropriately depleted, runs extremely perfect, with the goal that exorbitant cleanup or result removal isn’t required. A portion of the numerous laser etching items incorporate wedding giveaways, informal IDs, table nameplates, prize etching and laser wood etching.

Today laser etching can be utilized for the greater part of the positions as of now being completed by the customary modern etchers. A practical and flexible innovation is being utilized by numerous etchers to further develop efficiency, add more administrations for their clients and increment their benefits. Many organizations can be found internet based that make laser etching machines, laser stamping frameworks and laser drawing gear.