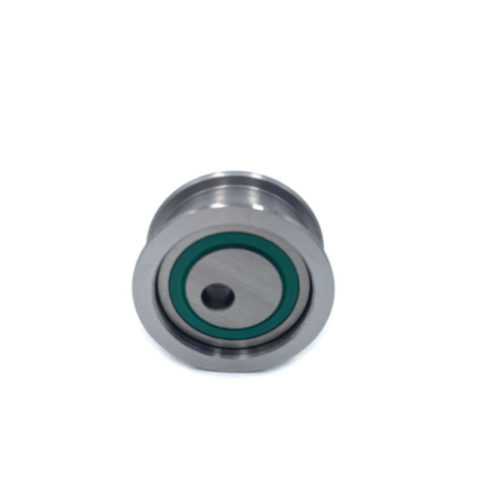

Here are some common maintenance procedures for tensioner pulley bearings:

Regular inspection.

China Tensioner Pulley Bearings suppliers manufacturers advice tensioner pulley bearings should be inspected regularly, ideally once a month or every 250 operating hours. Check that the bearings roll freely and smoothly without noise, wobble or excess heat. Ensure the tensioner arm is properly secured and tensions are appropriately adjusted. Address any issues to prevent bearing failure.

Lubrication.

Most tensioner pulley bearings require periodic lubrication to function properly and maximize lifespan. Use a high-quality grease or oil that is rated specifically for bearing applications. Grease tensioner bearings every 3-12 months depending on operating conditions. Oil-immersed bearings may require oil dips every 3-6 months.

Bearing cleaning.

Over time, tensioner bearings can accumulate dirt, debris and built-up contaminants which damage the bearings and reduce performance. Periodic cleaning helps ensure long term reliability. Use a solvent specifically designed for bearing cleaning and never use kerosene.

Belt and sheave alignment.

Misaligned tensioner pulleys that are uneven or off-center can quickly cause excess heat, wear and bearing damage. Ensure the tensioner pulley sheaves remain properly aligned with the belt they support according to the manufacturer’s specifications. Correct any alignment issues immediately.

Re-tensioning.

As belts age and stretch, periodic re-tensioning is required to keep tensions within allowable limits. Over-tensioned bearings suffer excess heat, noise and performance issues while under-tensioned belts slip or exhibit poor dynamic response. Have tensioner pulleys and belts re-tensioned by a certified technician according to the recommended schedule.

Replacement.

As with any bearing, tensioner pulley bearings will eventually wear out and require replacement. Check bearing condition regularly and replace whenever bearings show signs of significant damage like pitting, flaking or excessive wobble or noise. To prevent unscheduled downtime, replace tensioner bearings one warning sign at a time or according to the manufacturer’s recommended intervals.

High performance operation.

For heavy duty or high speed/load applications, more intensive maintenance procedures may be required to keep tensioner pulley bearings in reliable operating condition. Additional inspections, frequent lubrication, cleaning and re-tensioning help maximize performance and minimize failures under strenuous operation. Always follow recommendations from tensioner pulley and belt manufacturers.